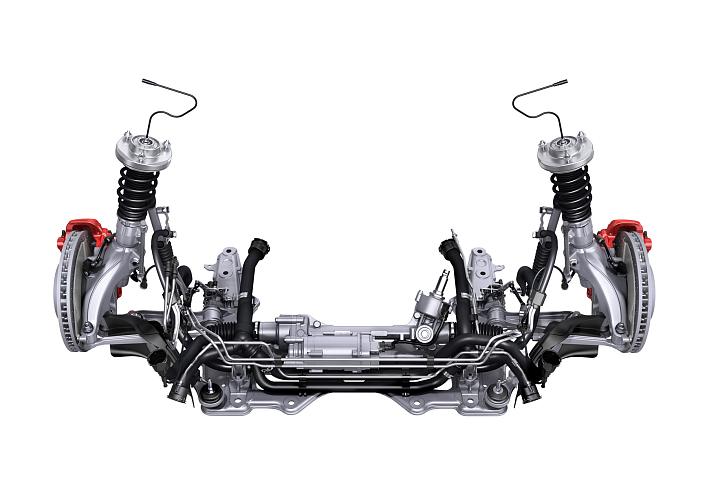

Сhassis

The details of the chassis and steering are included in the list of the most critical components of the vehicle to be regularly reviewed and replaced in a timely manner, and the safety of the end user is one of our principles. Taking into account this fact, we have entrusted the production of these product groups to proven manufacturing plants, including CTR, MANDO, LEMFÖRDER, BILSTEIN, KAYABA, SACHS and other world-famous manufacturers of automotive components of this segment.

CTR-one of the leading brands of auto parts for Korean cars and supplier to the conveyor of original spare parts for HYUNDAI & KIA, DAEWOO, GM and FORD cars, among which: elements of the engine and brake system, transmission systems, steering elements, suspension.

Today, the concern Central Corporation is the production of high-quality auto parts, in the manufacture of which the company uses the technology of highly accurate metal processing and development of its own design Bureau.

The range of products of this manufacturer includes more than 1000 items of auto parts for cars mainly of Japanese and Korean production. The share of products supplied to Korean conveyors is 15%. Basically, these are steering elements and suspension parts under the brand name "CTR".

The quality of products is estimated by world experts as above average. All products of this brand are original and certified both in the world market of auto parts and in Korean.

Every year, the Central Corporation concern produces more than 11% of the world turnover of auto parts for Japanese and Korean cars, descended from the conveyors of branded auto giants.

Halla production Corporation holds a special place among the suppliers of the Korean automotive industry. This position is due to the belonging of the head company Halla Group to the key economy of the Republic of Korea of HYUNDAI Empire.

The area of competence of Nalla can be divided into six key areas — suspension systems (shock absorbers of all types), brake system (hydraulics, calipers, electronic systems of stabilization and braking), steering (steering, columns, electric and hydraulic power), climate control, electronic components and seal parts.

The global production network of Halla Group includes 13 plants (enterprises are present in such countries as Brazil, USA, Europe, Japan, China, India, Turkey), 4 engineering and technology centers and 6 joint ventures (including Mando-Hella and Mando-Brose). South Korea has a major research center and several major factories — manufacturing brake systems, steering, shock absorbers, automotive electricians and sealing parts.

The German company LEMFORDER is a well-known European manufacturer of steering and suspension systems for cars and trucks.

The company is the official supplier of original auto parts for European, Japanese, Korean automakers. The history of the company began in 1947, when its founder, U. Ulderup, organized the production of ball bearings for the automotive industry in Germany. In 1984 the company became part of the industrial concern Zahnradfabrik Friedrichshafen (ZF).

Today, under the LEMFORDER brand, the products of the highest level of performance are manufactured according to the quality standards established by the manufacturers of original spare parts and components. ZF LEMFORDER industrial group as part of the ZF Group is engaged in the development and production of suspension, steering, rubber and plastic components. Under the famous company logo, 30 modern industrial enterprises are united in Germany, Spain, the USA, Japan.

Products for the conveyor and for the secondary market are produced on the same production lines. Certification of the company's enterprises according to ISO 9000, QS 9000, VDA standards is an additional guarantee of the quality of parts and components.

The main production areas:

- Steering links, levers and thrust rods.

- Cardan shafts, LEMFORDER SHRUSS and protective covers.

- Drive belts, rubber-metal products.

- Units and assemblies of hydraulic and braking systems.

- Silent blocks of the suspension, airbag casing.

- Stabilizers, LEMFORDER ball bearings and powertrain supports.

- Operating fluids: antifreezes, engine oils, brake fluids.

Already in 1957 the company BILSTEIN signed a contract for the delivery of its products to the assembly line MERCEDES-BENZ. From this moment on, to this day, the BILSTEIN brand is a symbol of reliability and durability of shock absorbers.

Today BILSTEIN, along with MERCEDES-BENZ, BMW and PORSCHE, is a symbol of the car industry in Germany. Behind the company's high-profile name is more than a century of history of development of German industry. Such a wealth of experience and dedication allow the company to produce products, which is by far one of the best in the world.

The central place in the company nevertheless belongs to the German enterprises. At the factory in Mandern, 15,000 shock absorbers, mostly "black ones," are daily produced for conveyor supplies. The most complex products are traditionally produced in Ennepetal, the generic nest of Bilstein. Here 5000 dampers are manufactured every day, but these are only single-tube "yellow" dampers. Many manual operations are carried out at this factory, and workers, many of whom have more than ten years of experience, are the most qualified here. Here is located the experimental and design center of the company. The production palette of Bilstein products is quite diverse. This is the Original Bilstein B2 / B4 spare parts program, the B6 Sport tuning program for installation with standard springs, the B8 Sprint program, in conjunction with the Eibach springs, the B 12 tuning kits. Recently, a new series of adjustable PSS / PSS9 suspensions has been added. In addition, shock testers, special components are offered. In each of these parts is the glorious 130-year history of Bilstein.

Such famous brands of cars as MERCEDES-BENZ, JAGUAR, PORSCHE, FERRARI, MASERATI are equipped on their assembly lines with BILSTEIN products.

The large Japanese corporation KAYABA is the world leader in the production of hydraulic equipment for cars and motorcycles (shock absorbers).

The company was founded in 1947. The headquarters is located in Tokyo (Japan). The Corporation owns 15 plants for the production of hydraulic equipment. The total number of employees is 11.5 thousand people. Currently, the company annually produces 75 million shock absorbers KAYABA. In the total turnover, the share of shock absorbers exceeds 50%. The largest plant is in Japan, its capacity is 48,000,000 shock absorbers per year. Other companies are located in the US, Europe and Asia. Most of the products are exported - KAYABA spare parts can be purchased freely in more than 100 countries.

Shock absorbers and KAYABA racks are delivered to the conveyors of the leading automotive manufacturers - 25% of the world shock absorber market belongs to this company. AUDI, ALFA ROMEO, FIAT, HONDA, FORD, MITSUBISHI, NISSAN, RENAULT, PEUGEOT, SUBARU, TOYOTA, VOLKSWAGEN and other corporations annually purchase over 50 million units of products under the brand KAYABA.

Separately it should be noted that regardless of the direction, all KAYABA shock absorbers are manufactured using the same technology and on the same production lines. All production is certified according to international quality standards: QS9000, ISO9001, ISO14001.

Kayaba shock absorbers are able to satisfy the demands of all consumers and provide a comfortable and safe ride. The program for the production of shock absorbers for the secondary market includes 6 production lines, on which:

- Hydraulic shock absorbers - Premium series.

- Gas-oil double-tube shock absorbers - the Excel G series.

- Monotube gas-filled shock absorbers - Gas-A-Just series.

- Sport shock absorbers for high-speed driving - Ultra SR series.

- Adjustable shock absorbers - AGX series.

- Shock absorbers for all-wheel drive vehicles - MonoMAX series.

In addition to the main products, the company produces individual parts: K-Flex springs, upper Mounting Kit supports, anthers and Protection Kit bumpers.

The German firm SACHS was founded in 1895. Manufacture of shock absorbers and clutches for cars was developed in 1930. Today, SACHS is the largest European manufacturer of parts and components for drive and suspension systems. The company's products go to assembly plants (original spare parts) and to the secondary market of spare parts. The company includes 39 industrial enterprises around the world. The company's share in the supply of original parts for European car factories is 80%. Each year, the company produces more than 500 million different shock absorbers and more than 150 million sets of clutches.

A significant part of the finished products under the SACHS brand is transferred to the conveyors of the leading car manufacturers: AUDI, MERCEDES, BMW, PORSCHE, OPEL, PEUGEOT, RENAULT, JAGUAR, ROVER, VW, MAN, IVECO, SCANIA, VOLVO, SAAB, FIAT, LANCIA, FORD, HONDA , VAZ, TOYOTA, MAZDA, NISSAN, MITSUBISHI. The extensive production program includes over 6,000 products under the SACHS brand:

- Shock absorbers for cars and commercial vehicles - SACHS telescopic shock absorbers, SACHS hydraulic and gas shock absorbers, ride height adjusters, variable damping systems, rubber parts, springs, anthers and shock absorbers for shock absorbers, bearing bearings.

- Transmission parts - SACHS clutch assembly, discs and clutch bags, flywheels, viscous coupling.

- Bearings - primary shaft bearings, thrust bearings, centering bearings.

- Professional tools and equipment for maintenance services.

The company SACHS has developed several series of shock absorbers, taking into account the style of driving and the requirements for comfort:

- Standard series «SUPER TOURING» (gas, hydraulic shock absorbers SACHS) - increased comfort on roads of any type during daily operation. For drivers with high demands on reliability and safety.

- Comfort series "ADVANTAGE" (gas-filled shock absorbers SACHS) - smooth movement, excellent maneuverability, excellent controllability. For those who appreciate the combination of excellent dynamics with a high level of comfort.

- Sports series "UNLIMITED" - absolute control over the car and accurate reactions on the road when driving at high speeds. Recommended for active drivers.

Excellent quality of shock absorbers and clutches SACHS is recognized all over the world: the clutch and shock absorbers according to their technical data fully comply with the strict standards of automakers.

The assortment includes:

- Shock absorbers

- Shock absorber supports

- Transmission parts

- Anthers

- Bumpers